Front Porch Blog

It has been three months since the ruinous Mountain Valley Pipeline became operational, pushing gas through its 300-mile path through the mountains and rivers of West Virginia and Virginia. The people who worked tirelessly to protect their communities over the past decade continue that good work: monitoring ill-planned restoration efforts, gathering as much safety information as available and supporting each other in this next stage of the fight.

Wrapped up in those safety steps are the requirements the Pipeline and Hazardous Materials Safety Administration included when it issued a safety consent order for the project last year. At the time, PHMSA, the federal agency that oversees all interstate pipeline infrastructure within the United States of America, recognized the danger of MVP’s degraded materials, reporting processes and pipe installation. The agency’s consent order laid out specific requirements for the MVP’s developers both for during construction and after the methane-gas pipeline became operational.

Some of those additional testing requirements are now due, but the agency is still lagging on communicating important information to the public. Additionally, a recent report from Mountain Valley Pipeline about the cause of their May 1, 2024, pipe rupture has brought little comfort to communities along the route.

What is listed in the PHMSA consent order?

The consent order, linked here, lists specific requirements about inspections, stating, “Within 90 days of commencing commercial natural gas transportation service on the Affected Facility, Respondent must run a high-resolution inline inspection (ILI) tool consisting of a magnetic flux leakage (MFL) tool with incorporated inertial measurement unit (IMU) and high-resolution caliper/deformation capabilities.”

This complicated phrasing describes placing a testing tool into the pipeline to assess its internal condition. It is meant to look for “excessive external stresses, including, but not limited, to all sag locations and tie in welds, and for any corrosion-related or other integrity-related conditions that require remediation…” With the significant number of pipe slippage which occurred in West Virginia portions of the route, this type of testing is critical.

In July, some landowners in Virginia reported subcontractors onsite who stated they were present for testing operations. PHMSA staff replied to a July Appalachian Voices inquiry on this subject a few weeks later to share that they were unable to confirm the nature or scope of the tests, and that MVP-hired contractors provide data and reports to the pipeline company directly, who then passes it along to PHMSA. This paper trail of testing schedules and results remains part of the opaque processes related to this ruinous pipeline. Additionally, the PHMSA reading room has offered very little new information in months, and an Appalachian Voices ‘July 1, 2024, Freedom of Information Act request for 2024 inspection reports is currently unfulfilled.

The consent order also lists that within six months of commission, which would be December 14, 2024, MVP must do a “close interval survey” to assess the pipeline’s cathodic protection system. Cathodic protection is a system that uses electrical current to ward off corrosion, but community members raised years-long concerns about the pipes’ protective coating, which degraded after years of direct sunlight in storage yards.

Pipeline Safety Trust’s Executive Director Bill Caram noted in a 2023 E&E News article that cathodic protection may not be sufficient to supplement coating degradation. He said, “Protective coating offers the first line of defense. Too many failures continue to be attributed to corrosion to assume cathodic protection will be enough.”

The order also lists that another review via tool run must occur within a year of the 2024 testing, to again look at sagged locations and welds. While these tests occur, community members and advocates will continue to seek timely information about the safety review processes, but the speed of information shared by the company and safety agencies reinforces how the public is purposefully kept in the dark.

MVP’s May 1 pipe rupture — what was the cause?

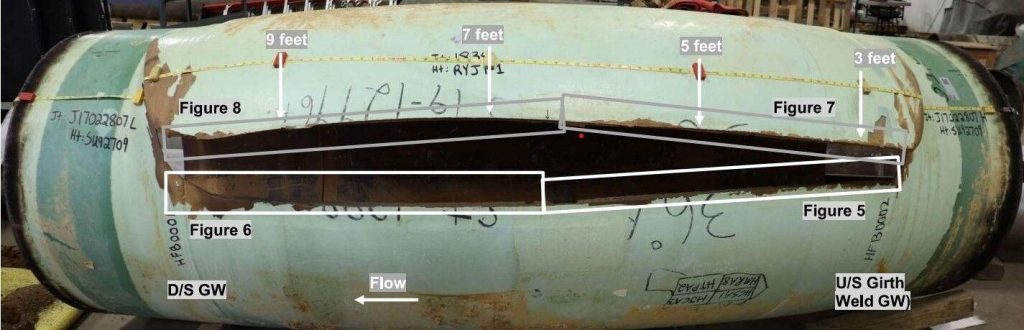

One of the most egregious examples of the failures of the project was a May 1, 2024, hydrostatic testing failure. When new sedimentation was spotted flowing into a Bent Mountain stream by a local citizen monitor, community members knew something significant had occurred during the hydrostatic testing of the pipeline. This process pushes pressurized water through the pipe to test seams and welds as well as the pipes themselves. What had caused the sedimentation was a catastrophic pipe rupture — and an observant local resident caught sight of the ruptured pipe as it was trucked away.

While downplaying the rupture as merely a sedimentation event in environmental filings, MVP took the pipe to a facility for metallurgical testing. Now, four months later, the company has released their report in a letter and attributed the rupture to a manufacturer’s defective weld. In fact, as detailed in this recent commentary, the report from the metallurgical testing company found multiple defects in both the welds and the pipe itself, and found additional defects in a second pipe that was tested.

The results of this report are cold comfort to those along the route, who’ve seen deficiencies in every stage of the Mountain Valley Pipeline’s wretched lifespan — from a dangerous route, to sediment-laden construction practices, the use of degraded construction materials and failures during testing.

Looking ahead

As deadlines approach for requirements of the consent order and restoration of the route proves increasingly ineffective in some counties, impacted community members and allied organizations like Appalachian Voices will continue to keep a watchful eye, and push for improved safety regulations. In 2025, those safety regulations will come into play when Congress works to reauthorize PHMSA via federal legislation that helps fund the agency.

And throughout the remainder of 2024, MVP fighters and advocates will continue to push back on proposals for additional new pipelines, like the MVP Southgate Extension and the Transco pipeline expansion, the Southeast Supply Enhancement Project.

PREVIOUS

NEXT

Related News

Leave a comment

Your email address will not be published. Required fields are marked *

4 responses to “Public left in the dark on safety inspection results after Mountain Valley Pipeline becomes operational”

-

And now with catastrophic flooding in the region, is there any required emergency inspection of erosion along or under the pipeline?

-

How can Virginia’s government be so stupid? The knowledge that pipelines are disasters waiting to happen is well known. Why did it take 4 months to release the report on that new pipe that ruptured? What is the company going to do to make sure none of the other pipes rupture? Safety is not the #1 concern where these pipelines are concerned — corporate profit and payoffs to state commissions are.

-

For the sake our our future generations and our environment, I wish these pipelines were not being built……especially as we move to alternative energy. BUT, with this pipeline being built, safety regulations MUST be improved.

-

This is amazing

Leave a Comment