High Stakes Gamble With Carbon Capture Technologies

By Bill Kovarik

Lake Nyos. Photo by USGS

A high stakes effort to research carbon dioxide capture and storage (CCS) technology is advancing with almost $2 billion in research and development grants, the Obama administration announced this February.

Four projects in West Virginia, Texas, Illinois and Alabama were slated in February for stimulus funding.

Dominion Energy’s Wise County, Va., power project, long touted as an advanced “clean” coal project, did not make the list. And the Alabama project has been cancelled by an electric utility based in Georgia. The three remaining projects will involve utility and coal industry contributions along with federal funding.

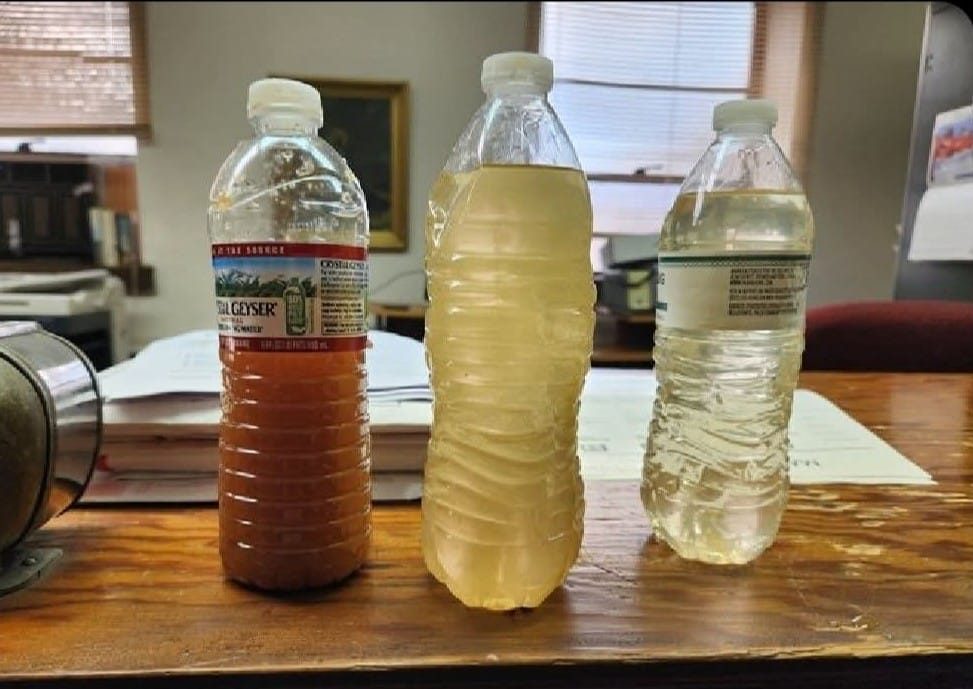

On August 21, 1986, Cameroon’s Lake Nyos suddenly released a massive cloud of CO2 into the air. The emission suffocated 1,700 people and 3,500 livestock in the surrounding area. Though this was a natural CO2 deposit, it raises concerns among some scientists about what could happen if CO2 artificially injected into the earth were to escape. Photo by Jack Lockwood, USGS

A new federal task force will also propose a plan “to overcome the barriers to the widespread, cost-effective deployment of CCS within 10 years, with a goal of bringing 5 to 10 commercial demonstration projects online by 2016,” the White House said.

At stake is the future use of coal to generate electricity while at the same time holding down carbon dioxide (CO2) emissions and staving off future climate change.

CCS technology involves pulling CO2 from the smokestacks of conventional coal power plants or from the incoming gas of more advanced coal plants. The advanced coal gas plants have strong advantages in terms of efficiently capturing CO2, but only a few of these new integrated gasification and combined cycle plants are under construction.

CCS research has skeptics and supporters

Both environmentalists and coal company executives have been skeptical of CCS.

“Geological carbon sequestration is a joke,” said Robert F. Kennedy, Jr., of the Waterkeepers Alliance in a West Virginia debate over coal and the environment held Jan. 21, 2010.

“That’s true,” responded Don Blankenship of Massey Energy Co.

“The costs will be prohibitive,” Blankenship said previously, in a November 2009 interview with The Hill, a Washington D.C., political magazine. “Basically, spending capital to triple the costs of your product is bad business even if it works–and ‘enviros’ will probably come after CCS if it begins to be very widespread.”

Others support the research.

“It’s one thing to argue that coal is not a viable technology because of mountaintop removal mining, because of air pollution, or because of coal ash disposal issues,” said Steven Smith of the Southern Alliance for Clean Energy.

“But we need an honest assessment of carbon capture technologies,” Smith said. “We support the Department of Energy’s research in this area.”

CCS technology isn’t cheap

The technology to separate carbon dioxide from other gases has long been known, but only in the past decade has research focused on the most economical processes for separating enormous volumes of gas.

The cost of carbon capture depends on various assumptions, but estimates range from a 25 percent increase to a doubling of electricity costs to consumers, who already pay an average of 12 cents per kilowatt hour nationwide.

While the oil industry routinely uses CO2 to force oil up from aging fields, in a process called “enhanced oil recovery,” large-scale storage has never been tried. Three major approaches to geological storage are contemplated, according to the Department of Energy: One drawback to coal bed methane is that “production water” from gas fields needs to be either treated or reinjected in non-freshwater aquifers. This is a major issue in shale gas development in Pennsylvania. Also, coal bed methane fields are closer to the surface and have a wider footprint, which means more landowners would have to be involved in negotiating liability issues. EPA’s endangerment finding for CO2 has made this area even more complicated. The biggest worry is that an accidental release of CO2 could be deadly. In 1986, a natural volcanic cloud of about 1.6 million tons of CO2 poured out of Lake Nyos in Cameroon (Africa), killing 1,700 people. Carbon capture and storage systems, however, are different. According to Nino Ripepi of Virginia Tech’s Center for Coal and Energy Research, the deep saline formations being used by the new CCS projects are over a mile and a half deep, and monitoring can be “stacked” to show leakage from a storage reservoir at many levels, long before it reaches the surface. “You can bet a lot of engineers are taking this very seriously,” Ripepi said. EPA, especially, is working on licensing and safety standards. Another problem with CCS is that the sheer volume of the infrastructure needed for a serious long range CO2 reduction program is daunting. Energy analyst Vaclav Smil has pointed out that even a 10 percent CCS program for all global CO2 emissions would be the size of the entire global oil industry. “Even if we were to embrace this second-rate option, the magnitude of the enterprise needed to make a real difference will defeat us,” Smil said.

• Oil and gas fields, where CO2 is widely used;

• Deep saline structures, with hundreds of gigatons of storage capacity in formations 9,000 feet deep; and

• Coal bed methane deposits, more typical in Appalachia, around 4,000 feet deep.

Related Articles

Latest News

Leave a comment

Your email address will not be published. Required fields are marked *

Leave a Comment